Biogas Desulphurization System

Zhengze Biogas Desulphurization System Biogas is an important renewable energy source. However, the gas originating from anaerobic digestion plants, anaerobic wastewater treatment plants and landfills often contains hydrogen sulfide (H2S).

Zhengze Biogas Desulphurization System

Biogas is an important renewable energy source. However, the gas originating from anaerobic digestion plants, anaerobic wastewater treatment plants and landfills often contains hydrogen sulfide (H2S). Removal of H2S is necessary for reasons of personal health, safety, environment and corrosion of equipment such as gas engines, boilers and piping.

By continuous development Zhengze is able to provide customers with a tailor made gas treatment system that enables customers to upgrade gas to bio-methane. The residual Elemental Sulphur produced by the system can be used as high quality fertilizer.

Advantages of Zhengze Biogas Desulphurization System

• Simple technical process, only 3 units

• Deep H2S removal

• High uptime and reliable process

• No air or oxygen input in biogas

• Fast start-up/Commissioning

• High degree of automation, unattended operation

• Comparing with other solution,

-- Installed power, reducing 30-60%

-- Operation cost, saving 50-70%

-- Small foot print, saving 50-60%

Operation principle

The ‘caustic’ solution in the scrubber is continuously and biologically regenerated. In the scrubber, the gas containing H2S rises in the chamber and is brought into contact with the washing solution spaying down from the upper chamber.

Absorption of H2S under slightly alkaline conditions (pH 8-9) enables a chemical reaction with hydroxide ions:

H2S gas + OH- → HS-liquid + H2O

In the bioreactor the sulphide is oxidized into elemental Sulphur by autotrophic colorless Sulphur bacteria:

HS- liquid + ½ O2 → So + OH-

The hydroxide used in the scrubber is regenerated in the bioreactor. Since the washing solution entering the scrubber at the top is sulphide-free, a high concentration difference between the liquid and gas phase makes it possible to obtain a very high H2S removal efficiency, exceeding 99.5%. Both the small bleed stream (consisting of sodium salts) and the produced Sulphur is free of Sulphide, so they can be easily disposed.

Application

The scrubber can be applied to a wide range of biogas streams containing H2S and can be combined with all biological anaerobic systems.

After treatment in the scrubber, the biogas can be safely used in a generator engine or boiler or transported in a local micro gas grid. Upgrading to bio methane, which can be brought into the gas distribution network or use as fuel for vehicles is another possibility.

• Gas flows from 50 to 2,500 Nm3/h

• Sulphur load up to 600 kgS/day

• Custom made design for higher gas flows. References for > 10,000 Nm3/h and Sulphur loads > 5 ton S/day

Zhengze Biogas Desulphurization System, how it works

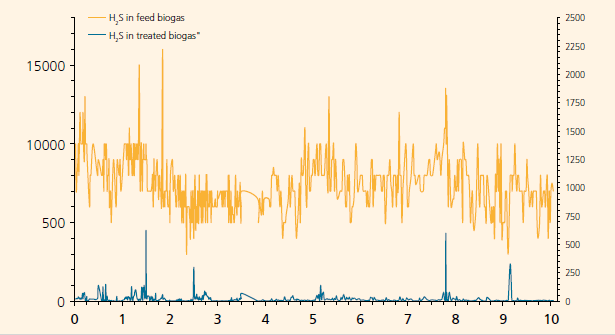

Influent independent, stable performance

How it works

1. H2S-rich gas in

2. Purified gas out

3. Alkaline wash solution, (absorbs H2S from the gas)

4. Sulfide rich solution from scrubber into bioreactor

5. Air for Sulphur oxidation reaction (sulfide to Elemental Sulphur)

6. Sulphur separated